The idea behind sand compaction is to press together its particles, making it denser. Compacted sand can be used in different areas of landscaping. If you are wondering how much sand can be compacted, we did comprehensive research to find an answer for you.

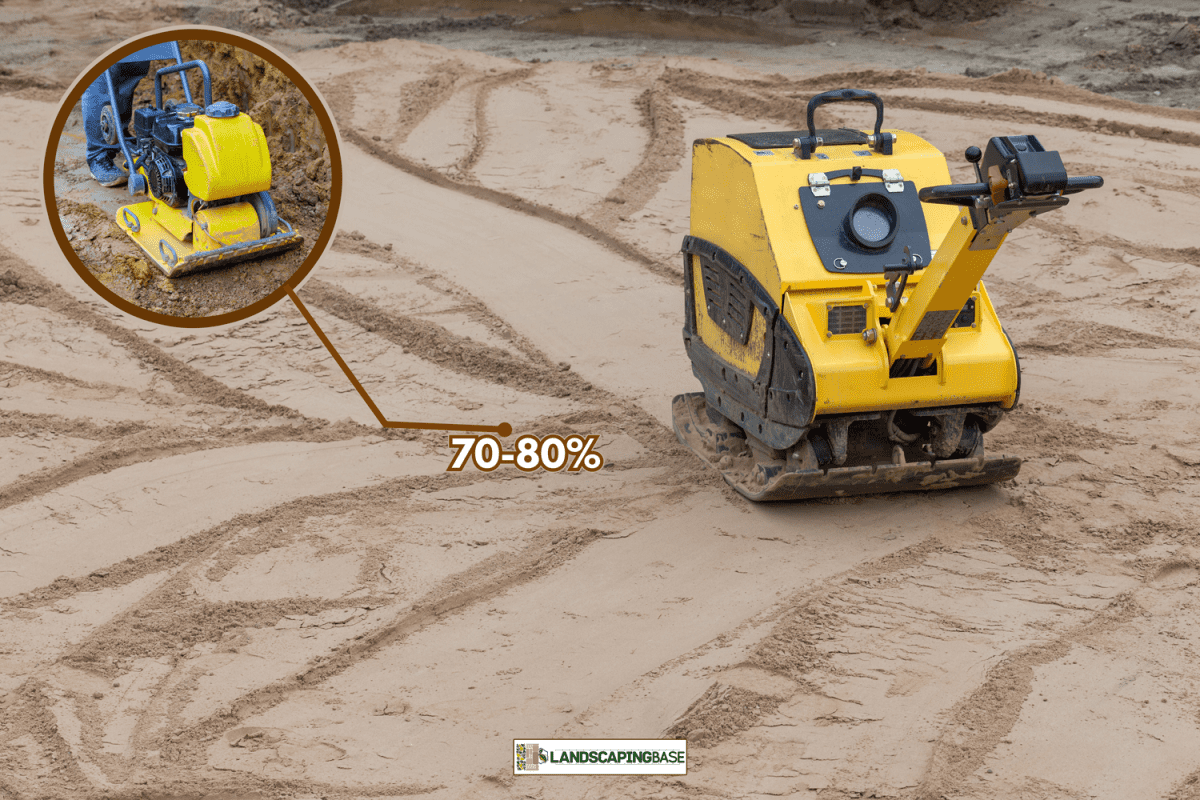

Sand has a high compaction rate. It can be compacted to a relative density of about 70 - 80%. Many people use sand to fill areas because it is affordable and attractive. To optimize sand compaction, water is added to fill up its voids and hold the particles together.

A solid sand base is a good foundation on which other parts of construction depend. Keep reading as we explore more on sand compacting.

How Much Does Sand Compact?

Sand compaction increases density either by using water or mechanical methods. This packs the sand particles together, thereby reducing the air gaps, resulting in a homogeneous sand mass with stronger properties.

Sand compaction can range from 70-80%. Its changes can bring about desirable properties like:

- Increased strength

- Minimized settling

- Laid-in designs

- Reduced permeability

- Increased density

- Reduced erosion

Factors That Affect Sand Compaction

Some factors that affect sand compaction are:

Compaction Effort

Most major projects use heavy-duty compaction machines to provide enough force. The type of machine selected would normally depend on the type of soil. Compaction methods are classified into four types: kneading, static, dynamic or impact, and vibratory.

Different actions are effective for different soil types. For example, vibratory compactors are the most effective for compacting sandy and gravelly soil.

Moisture Content

The moisture content of sand or soil can be a determining factor when trying to achieve the desired density. You can reach maximum density with minimum compaction effort when compacting an optimum moisture content (OMC).

If the soil's natural moisture content is less than OMC, a calculated amount of water must be added to bring the soil to uniform moisture content. And, if the soil has excess moisture, it must be dried to reach the OMC.

Type of Soil

The type of soil has a significant impact on compaction characteristics. Heavy clays and silt are typically more resistant to compaction, whereas sandy and gravel soils are easily compacted.

In comparison to clay, coarse-grained soils have higher densities. You can increase the density of well-graded soil by compaction.

How Do I Make Sand More Compact?

You can compact sand by adding the right amount of water or using a compactor. Either is necessary to reduce the porosity and increase the stiffness of the soil.

When using water, it is recommended to:

- Trickle water over the sand until it forms a pool on the surface. Use a low-pressure sprinkler, so the sand has enough time to absorb the water.

- Allow the water to soak for about one hour.

- Allow the water to absorb completely before sprinkling more water until a pool is formed on the surface.

- Use a lawn roller, or you can walk over the moist sand to make it compact.

Sand and gravel are frequently compressed using a compactor. These machines have large engines mounted on top of a plate that causes the plate to vibrate.

Since compaction is important in any type of sand project, it is important to utilize the right type of compaction equipment. Some types of compactors include:

Jumping Jack

It is more focused and direct because of the smaller plate size. They are ideal for trenches and tight spaces that other compactors might find difficult to maneuver. Each stroke carries a heavy impact that provides a deeper compaction depth when compared to a plate compactor.

Pedestrian Roller

Also called a walk-behind roller, is better suited for large areas that require compaction. The advantage of a pedestrian roller is its ability to travel faster; therefore, it covers a larger area faster.

Plate Compactor

Plate compactors are wider compared to jumping jacks, distributing their weight and compaction force over a larger area. It is ideal for granular soil, flat and larger surfaces. These machines leave a smooth finish.

Check out this plate compactor on Amazon.

Precautions When Using a Plate Compactor

Using a plate compactor, you can follow some safety tips to get your work done efficiently.

- Wear noise protection, such as earplugs.

- Warm the engine but run it at idle speed for a short time before you start working.

- Do not turn off the engine directly from full speed; let it run slowly for a while to enable the temperature to equalize.

- Maintain a frame footing to avoid slips and falls when starting or operating the compactor.

- To ensure that your machine moves freely and avoids the build-up of materials, clean the plate regularly.

How Much Does Sand Shrink When Compacted?

The shrinking percentage of sand when compacted ranges from 11 - 35%. Shrink is the change that can occur due to loss of moisture content.

How Do You Calculate Shrink and Swell? [In Sand]

Shrink and swell are used to estimate the volume of change an excavated material undergoes from its natural state to its compacted state.

Swell is the increase in the volume of sand once it has been excavated from its natural state. It can be calculated as follows:

- Swell = volume of sand after excavation/volume of sand before excavation

Shrinkage is the decrease in the volume of sand after it has been compacted from its natural state. It can be calculated as follows:

- Shrinkage = volume of sand after compaction/volume of sand before excavation.

What Does It Mean to Have 95% Compaction?

This means that the soil has been compacted to 95% of its maximum density. It is a common target -predetermined by laboratory testing- to ensure building sites have a strong foundation. It can vary, however, depending on the load-bearing capacity necessary for the intended structure.

Does Sand Compact Better Than Dirt?

Dirt and sand are both extracted from the earth for use in construction, but their composition and physical properties are vastly different.

Dirt comes from beneath the topsoil because this layer has little to no amount of organic matter. As a result, it is difficult to shift or disintegrate over time.

Sand, on the other hand, is made up of minute rock particles that have been eroded and broken down over time.

Like dirt, sand has a high compaction rate, capable of forming a solid, stable foundation. It compacts better because the sand particles are round and can be easily displaced.

While it is not used in every situation, dirt is often the best choice when making compacted foundations such as those seen prepared for roads and buildings.

These projects require a completely immovable base. Dirt is also a versatile material that can fill and level out hills or fill in gaps where underground pipelines exist.

Will a Dozer Compact Dirt?

Dozers do not compact dirt. A dozer is mainly used for demolition and pushing operations. They are used to clear an area of waste and vegetation. Bulldozers move on strong, heavy metal tracks, making them perfect for uneven terrain.

Should I Wet Sand Before Compacting?

Yes, you can wet sand before compacting because the best result from compacting is derived when your sand is at its optimum moisture content (OMC). At this level, there is enough moisture to hold the sand particles together, so they do not slide against each other.

Ensure that the moisture content is correct; incorrect moisture content will result in more viscous sand.

Sand, in particular, is difficult to compact due to its granular composition. As a result, if you plan to prepare a paver bed, you should consider compacting the bottom layer of soil or dirt before laying a layer of sand.

Is Sand Cheaper Than Gravel?

The gravel cost varies depending on the type but can range from $10 to $50 per ton. It ranges from 4.75 mm to 75 mm, larger than sand.

Sand costs between $5 to $30 per ton. Its size ranges from 0.0075 mm to 4.55 mm. Sand may be less expensive or more expensive than gravel, depending on the type.

Conclusion

Soil compaction is usually achieved when its particles are pressed together to reduce the space between them. Compaction reduces the likelihood of shrinkage.

Apart from using water to fill sand pores, the best results are achieved by using compactors to vibrate its particles. Vibration and plate compactors are recommended for sand compaction.

![A man using a portable vacuum to collect dead leaves, Will A Leaf Vacuum Pick Up Mulch? [Can It Remove Leaves From Mulch?]](https://landscapingbase.com/wp-content/uploads/2022/09/Man-using-a-portable-vacuum-to-collect-dead-leaves-600x400.jpg)